|

High Speed Rail IDEA Project 28 [Completed (IDEA)]

Development of a Commercial-Grade Bi-Axial Strain Transducer

| Project Data |

| Funds: |

$145,000 |

| Staff Responsibility: |

Chuck Taylor |

| Completion Date: |

9/1/2004 |

| Fiscal Year: |

2001 |

|

The collection and analysis of data on the fatigue history of high-speed railroad components such as rail, bridge members, and wheels is extremely difficult using traditional sensors and data acquisition systems. Strain-gauge systems typically require cumbersome data collection, preprocessing and storage devices, signal processing devices, substantial power sources, and complex wiring. And these systems do not provide high resolution and are not drift free. Uni-axial and bi-axial strain transducers are micro-electromechanical systems (MEMS) with such characteristics as high resolution and high sampling rate, absolute encoding, no calibration requirements, no drift over time, and less measurement noise than analog-based strain sensors. They measure strain by measuring the displacement between two overlapping pads attached to a structure such as a beam or rail. One pad contains an array of electrostatic field emitters, and the other pad contains an array of field effect transistor gates on an IC chip. Displacement of one pad relative to the other pad causes the emitters to move over the surface of the IC chip. Digital processing of the resulting signal is used to calculate strain.

The system can measure displacements as small as 50 Angstroms (5 × 10-7 cm). The sensor sampling rate is dynamically configurable and up to 128 sensors can be linked on a common 5-wire digital bus, eliminating the need for shielding and considerably reducing the number of wires which have to be routed through the structure to be measured. Because they have low DC power requirements, they can be used in remote locations. The small size and on-chip signal processing features provide the potential for a truly portable testing device.

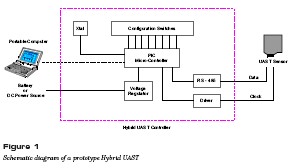

The objective of this research was to determine the potential of these transponders as a new tool to continuously monitor, analyze, and store the strain history of components such as rail. This data could be periodically downloaded and used for such purposes as measuring rail stress induced by axle loadings or thermal loadings. The research was to develop a prototype transponder system, which includes nonvolatile RAM to store strain cycling history, e.g., tracking how many times the transponder crosses each of specified strain thresholds across its dynamic range, and temporarily storing the preprocessed data. The prototype system consists of three parts, a sensor, a networking controller box, and a communication cable. Figure 1 shows a schematic design of a hybrid uniaxial strain transducer (HUAST) controller to be operated by a battery. A load cycle counting algorithm is integrated into a microcontroller, which is programmable using configuration switches. Using this HUAST controller, eight different strain levels can be collected at four different sampling rates.

|

|