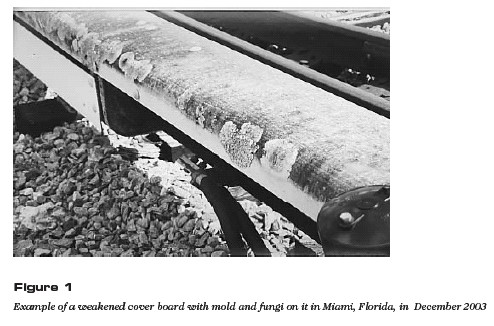

This project developed and tested a prototype device to clean and recoat the cover boards on electrified third rails for rail rapid transit systems. The ultraviolet action of the sun on the fiberglass reinforced plastic cover board degrades the protective gel coat and then delaminates the glass fibers.

The weakened cover boards sometimes flutter excessively from the draft caused by trains and from high winds. The holes in the cover board for the retaining pins become enlarged and the pins can slip out. The cover board can drop on the third rail. The contact shoes, which slide on top of the third rail and provide power to the traction motors, break off when they hit the dropped cover board. Traction power is lost and the rail system shuts down. The high voltage and access restrictions to cover boards make them difficult to clean and recoat.

Rail rapid transit systems often need to replace third rail cover boards at considerable cost. One agency is replacing all their cover boards that are only 20 years old, at a cost of several million dollars. The prototype device developed in this project will be tested on the Miami-Dade Transit (MDT), Los Angeles County Metropolitan Transit Authority (LACMTA), and Metropolitan Atlanta Rapid Transit Authority (MARTA) rail rapid transit systems, with the participation of those transit agencies. Other rail rapid transit systems, including the Washington Metropolitan Area Transit Authority (WMATA) MetroRail system, the Maryland Transit Administration (MTA) Baltimore rail rapid transit system, and the Bay Area Rapid Transit District (BART), have also indicated a need for a cover board cleaning and recoating system, and will participate in this project. The cover board cleaning and recoating system will improve the safety and security of rail transit systems and will enhance public perception and confidence in the security of rail transit systems.

Completed Investigation

This project has developed and successfully demonstrated a prototype two-component recoating system.

A two-component, spray-applied recoating system was developed into a prototype that was mounted on a service vehicle driven on the tracks and tested and evaluated at the MARTA, Miami MDT, and BART rail rapid transit systems, with the participation of those transit agencies. WMATA, MTA Baltimore, and LACMTA participated in this project and provided guidance to the principal investigator.

Product Payoff Potential

The recoating system could offer rail rapid transit agencies a tool that would restore third rail cover boards in place in an efficient and cost-effective manner and improve the safety and reliability of those transit systems.

Product Transfer

The prototype third rail cover board recoating system was tested on the MARTA, Miami MDT, and BART rail rapid transit systems. The results are included in a final report for this project, and have been disseminated by the Principal Investigator via papers presented at professional meetings, and APTA rail conferences.

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/transit/Transit44_Final_Report.pdf