|

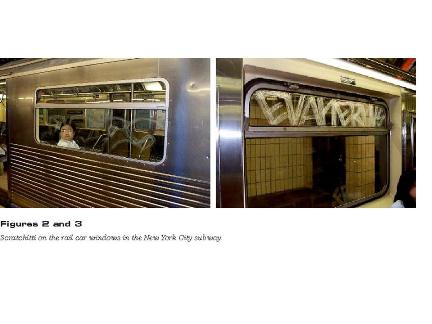

This project addressed the problem of vandalism on rail transit car windows. A type of graffiti vandalism that has emerged and prevails is the scratching or etching of polycarbonate and glass windows in subway cars, called “scratchitti.” Unlike paint graffiti, the scratches cannot be removed or covered, and they cause permanent damage.

New York City Transit supported this project from the time it was proposed and has collaborated in providing samples of scratched glass subway windows to Columbia University to test and characterize.

To address the problem, this project used an innovative approach—controlled fire polishing, which incorporates a technique of localized softening and surface tension. Intensive heat is positioned near to the scratch marks on the glass panel. The heat melts a thin layer of glass into liquid, changing the glass’s viscosity to a formable state. The glass is melted to a level close to the depth of the scratch, and allowed to cool down naturally. During the cooling process, the surface tension of the melted glass evens out the scratching indent. After cooling and without grinding or polishing it, the glass is as even and smooth as it was originally. In this process, the glass remains solid and structurally sound during this operation to prevent any distortion of the glass panel. This process can flatten and smooth the surface and restore its optical transparency, in an environmentally safe manner. It can significantly reduce costs compared with replacing subway car windows.

Project Results

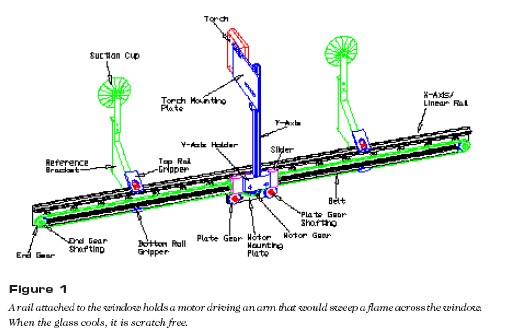

This Transit IDEA project has successfully demonstrated the feasibility of this innovative process in the laboratory. Investigators at Columbia University surveyed and characterized the scratchitti, investigated the glass or polycarbonate properties, designed the heat source, ran a heat transfer analysis and temperature computer simulation, and designed and built a motor-driven prototype tool for removing scratchitti for initial tests. The project has demonstrated the feasibility of the proposed system and collected the necessary data and parameters for controlling the process.

To facilitate the smooth operation, a uniform, linear, narrow, and high-temperature flame served as the heat source and provided a cost-effective tool for fire polishing. This was achieved through three iterations of nozzle development. The machine investigators designed and built Scratchitti Buster, a motor-driven slider controlled by a computer to move the nozzle at a constant speed during the polishing process. Light and portable, this machine has suction cups to cling to the glass panel for positioning. It uses the glass surface as reference by a pair of brackets so that the nozzle will keep a constant distance while moving. The brackets are adjustable to fit the machine with different sizes of windows. The oxy-fuel used can be acetylene-oxygen for high-speed fire polishing or propane-oxygen for convenient and easy operation.

Analytical and numerical heat transfer simulations of the flame and glass pane interaction yielded satisfactory operational parameters for the desirable steady-state temperature distribution. The control parameters included the flow rates of the fuel and oxygen and their mixing ratio, and the flame travel speed and distance from glass surface. The desirable temperature distribution enabled the glass surface to re-flow and remove etches, while preventing glass distortion and cracking. Experimental testing of the fire-polishing process was performed, and the feasibility of the process was demonstrated by glass samples that recovered from heavy scratches to a smooth, clear, and transparent state. The ranges of optimum operating parameters for high polishing quality have been identified through a range of testing conditions.

Project Payoff Potential

This project addressed the pressing scratchitti vandalism issue faced by rail transit agencies operating subways. Unlike paint or ink graffiti, the glass etchings cause permanent damage. Scratchitti is prevalent on many subway car windows of New York City’s subway lines. Because replacing the damaged window is so time consuming and costly, transit agencies have not been able to replace all of the damaged windows. Currently, New York City Transit (NYCT) replaces glass only when it becomes so scratched it cannot be seen through, or when it has obscenities or racial slurs etched into it. In 1997, NYCT replaced approximately 62,000 pieces of damaged subway window glass for a material and labor cost of $2.6 million. NYCT has estimated that, in order to run a scratch-free subway rail car fleet, they would have to spend $60 to $70 million per year in window replacement and labor costs.

Product Transfer

A process demonstration was performed at Columbia University for representatives from New York City Transit who have supported this project from its beginning and have provided assistance to the researchers. The results from this Transit IDEA project have successfully demonstrated the feasibility of this innovative process in the laboratory. The final report for this Transit IDEA project has been completed.

The information from this project could serve as a basis for product development and design in commercialization stages. It could move into development of an operational instrument. Following this project, the investigators propose to develop a well-controlled operational instrument or tool for removing graffiti from subway car glass windows, based on the results of this project, if they can find financing. A private company obtained a license for the technology from Columbia University. A follow-on effort has been pursued with private resources to deal with automating this graffiti removal system.

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/transit/Transit28_Final_Report.pdf.

|

|