Both the US and the UK have significant concerns regarding the condition of post-tensioned segmental concrete bridges. The problem is that it is difficult to ensure proper grouting of posttensioning tendons. When post-tensioned ducts are not completely grouted, and voids are present, the steel tendons are left vulnerable to premature corrosion.

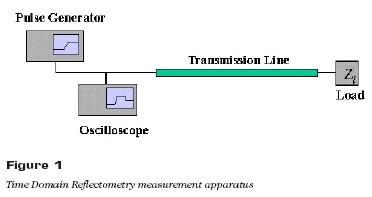

The goal of this project is to develop an effective and economic nondestructive evaluation (NDE) procedure that will allow bridge owners to ensure that post-tensioned ducts are properly grouted (i.e., have no voids). The proposed NDE procedure will utilize Time Domain Reflectometry (TDR), a technique developed years ago by electrical engineers. TDR was originally developed to detect discontinuities in transmission lines. The technique involves sending a signal through a transmission line using a pulse generator, seeing whether or not the signal is reflected back using an oscilloscope, and, if it is reflected back, using the time elapsed to determine the location of the discontinuity. The necessary measurement apparatus is shown in Figure 1. To detect and evaluate voids, the transmission line is placed either in or adjacent to the region in which a void is suspected. The presence of a void affects the electric field surrounding the transmission line and causes a reflection. Investigators previously used TDR to locate and evaluate corrosion sites on concrete-encased steel strands by observing reflections of the pulse from damage sites (see ASCE Journal of Materials in Civil Engineering Vol. 14, Issue 3 (2001) pp. 217-223). In that case, the strand was used as one wire of the transmission line and a parallel sensor wire was added as the other. The corrosion represented a partial discontinuity in the line. In the case of a void, the discontinuity is in the material surrounding the transmission line. Such a change will also cause a reflection of the signal. In fact, preliminary studies indicate that the reflection due to a void is far stronger than that due to corrosion damage. The final report is available from the National Technical Information Service (NTIS # PB2007-105554).