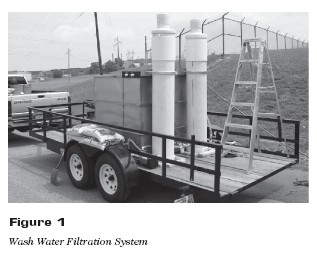

This project designed and tested a filtration system (Fig. 1) for removing both particulate and soluble lead from wash water generated by pressure washing of lead-based paint from highway bridges during painting operations. The filtration system relies on a granular compound capable of chemically binding free lead into an insoluble lead mineral. A literature search identified several commercial hydroxypyromorphite compounds suitable for binding lead in an aqueous environment along with many apatite minerals that appeared to stabilize lead. Bench-scale testing of three commercial filter media containing lead-stabilizing compounds, based on aluminum silicate and calcium phosphate, were conducted under simulated field conditions. All three systems performed adequately in removing both total and dissolved lead from the synthetic effluent. Based on test results and cost considerations, LeadX was selected as the primary medium for lead removal. A full-scale prototype filtration system capable of handling 400 gallons of water per hour was designed, fabricated. It consisted of a flow equalization tank followed by a trickling sand filter (to remove large particulates) and an upflow filter column containing the filter medium. The prototype was tested on two bridge washing projects at two locations in Kentucky. In both instances, the filtration system proved effective in removing lead from the washwater. The total lead concentrations were reduced to 20 ppb or less from 10 ppm. The Kentucky Transportation Cabinet has expressed interest in using this system. The final report is available from the National Technical Information Service (NTIS # PB2003-102869).

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/highway/NCHRP072_Final_Report.pdf