This project designed and produced dual-phase ferritic martensitic (DFM) reinforcing steel with improved mechanical properties and corrosion resistance. DFM steel is a low-alloy, lowcarbon steel produced by simply quenching the alloy from the two-phase ferrite/austenite field, thus producing a mixture of ferrite and martensite. The major strength source in the DFM structure originates from the presence of the inherently strong martensite phase, which provides the load-carrying constituent of the alloy. The soft ferrite phase provides the alloy with ductility.

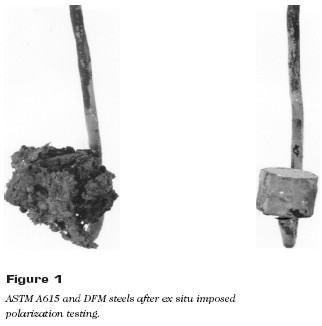

Electrochemical evaluations were performed for in situ and ex situ conditions. The ex situ electrochemical test results provided different conclusions on the performance of the reinforcing steels. Anodically polarizing the steels in a de-aerated, decanted cement solution with 3.5% NaCl indicated that the DFM steel is more resistant to corrosion (Figure 1), while the ASTM A615 steel shows substantial corrosion products from the exposure. ASTM G-61 results indicate that the DFM steel is more susceptible to chloride-induced localized corrosion in the decanted, de-aerated cement solution. The ASTM G-61 results did not correlate with the in situ testing results and further investigations are required to determine these discrepancies.

In situ testing included Lollipop mass loss testing, Southern Exposure macrocell current testing, and Southern Exposure mass loss testing. All in situ tests indicated that the DFM reinforcing steel was more resistant to chloride-induced corrosion when embedded in concrete than commercially available reinforcing steels. The investigator is negotiating with Nucor Steel, a steel manufacturer, for production of a 50-ton heat of DFM steel. Since Nucor Steel does not have an on-line quenching, the steels must be heat treated following rolling. Bars from Nucor will be tested for mechanical and conversion properties. The final report is available from National Technical Information Service (NTIS #PB-139060).

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/highway/NCHRP028_Final_Report.pdf