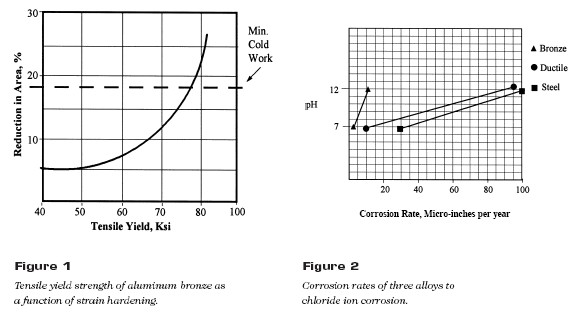

This project evaluated aluminum bronze alloy as a possible alternative to steel for corrosionresistant concrete reinforcement. Rebars from aluminum bronze alloy were fabricated for laboratory and field evaluations. Initial tests showed rather low mechanical properties for alloys as compared to steel. Further work focused on improving the strength and mechanical properties of the alloy by optimizing its composition and fabrication process. The process eliminated the hot rolling operation and entailed direct continuous casting of aluminum bronze to a near net size and shape of rebar followed by cold drawing the bar to finished size and shape. The cold drawing operation increased the strength of aluminum bronze rebars close to that of mild steel rebar, meeting the ASTM specifications (Figure 1). In corrosion tests, the aluminum bronze alloy showed high resistance to seawater corrosion as compared to mild steel and ductile steel (Figure 2). Cost analysis of aluminum bronze rebars showed a cost of $0.85 per lb. as compared to $1.20 per lb. for stainless steel at current metal prices. The final report is available from the National Technical Information Service (NTIS # PB97-141972).

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/highway/NCHRP019_Final_Report.pdf