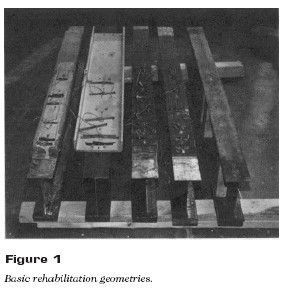

This project evaluated the feasibility of using advanced composite materials for rehabilitation of steel highway bridges as an alternative to conventional repair methods. Stage 1 work performed modeling, fabricating, and testing of two flange repair schemes and proved the feasibility of the concept. Service-load testing on the repair schemes verified that the composite plates increased the stiffness of a section. A finite element model was applied to determine the desired geometry of the composite plate. Rehabilitation schemes were developed and tested for a variety of field geometrics. Figure 1 shows various rehabilitation concepts. Test results showed good agreement with model prediction for stiffness enhancement. Increases in girder flexural modules of 20% to 30% were found to be attainable, which corresponds to the level of losses expected to be of concern in deficient bridge girders. Sandblasting the steel surface and using a saline pretreatment resulted in best durability for most adhesives. Results also show accelerated bonding through induction heating to be a viable rehabilitation technique in the field. Work in Stage 2 involved additional service load testing of fabricated scale beams, adhesive durability testing, and large scale testing of composite repair of both virgin and corroded steel beams. The results show improved strength and fatigue life of steel components by composite materials. A failure mode of concern is that due to bond failure, which occurred frequently in small tests. This failure, however, did not occur in large girder tests. Field validation of the technique is required for product transfer to practice. This is planned in a follow-up NCHRP-IDEA project in collaboration with the Delaware Department of Transportation. The final report is available from the National Technical Information Service (NTIS # PB97-141964).

The final report for this IDEA project can be found at:

https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/highway/NCHRP011_Final_Report.pdf