The project developed guidelines for using sprayed zinc (as a sacrificial anode system) for protecting reinforcing steel (acting as the cathode) from corrosion in marine bridge structures. Sacrificial cathodic protection by means of sprayed-zinc galvanic anodes is a low-cost alternative to conventional cathodic protection of these substructure components. The surface of the spalled concrete and exposed rebar is abrasively cleaned and sprayed with zinc, using commonly available metallizing equipment. An electrical connection between the zinc and the steel is established directly. Concrete patching is not needed unless required for structural reasons, in which case the zinc is applied over the repaired concrete and a stud is used to connect the steel with the sprayed zinc. The finished cost ranges from $60 to $120/m2. The method is applicable to a wide variety of structural components.

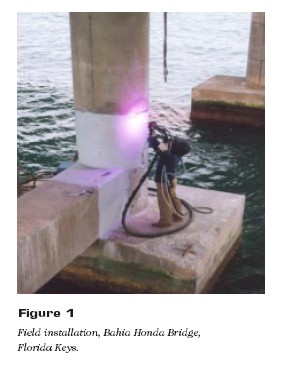

Laboratory and field experiments demonstrated the feasibility of the proposed approach. Additional performance data were obtained in a large-scale field application (Figure 1). The fieldwork was carried out in collaboration with the Florida DOT during the rehabilitation of the Howard Franklin Bridge on Tampa Bay (State Project 15190-3487). The tests showed adequate probe and steel polarization (typically exceeding the 100-mV depolarization criterion) with moderate current demand (below 1 mA/sq. ft.) indicating continued cathodic protection of steel reinforcement in the substructure. Based on field results, a manual on the use of sprayed zinc for the protection of marine substructures was prepared. The product is undergoing large-scale field trials by the Florida DOT. A special two-page IDEA product report, Sacrificial Sprayed-Zinc Galvanic Anode System for Corrosion Protection of Reinforced Concrete in Marine Substructures, was released in June 1995. The final report is available from the National Technical Information Service (NTIS # PB97-141766).